Results of the 2nd annual Insect Industry Survey, part 3 of 3

In this 3rd and last part of digging deeper into the Insect Industry Survey results, we will cover topics such as finding new sales channels, biggest obstacles, biowaste, production sizes and the product pricing.

In case you missed the first two parts of the results, you can find them here:

Results of the 2nd annual Insect Industry Survey, part 1/3

Results of the 2nd annual Insect Industry Survey, part 2/3

With the third part of the results, let’s start with the sales channels. We asked our survey respondents if they would be interested in finding new sales channels for their insect farming products or would they be interested in finding insect products, training, tools or services to buy?

Almost 60% of the responders to the Insect Industry Survey stated being interested in finding new sales channels, and approx. 35% were looking for new purchasing channels. Some of the respondents were interested in both. Only 3,70% were satisfied with their current sales or purchasing channels.

The Marketplace

Good news: There is a Marketplace for insect farming related products and services being launched officially around the 3rd week of February (2025 of course), and we’re currently testing the final features for it. You can already add your products for sale for free – no advertising fees, no sales provision, no cost whatsoever for either the seller or the buyer! And if you list your products or services for sale before February 17th, you get to enjoy some extra visibility, as we’ve already started the first advertising campaign in Africa to attract poultry farmers to use the Marketplace to find BSF larvae (live, dried, etc.) from our Marketplace sellers. More advertising will be starting in February to attract even more people and organizations to the platform, which already has almost 2000 registered users!

You can find the Marketplace with a couple of first sellers listing their products already at the Insect Farm Hub (https://insectfarmhub.com/), which has also other notable free features for anyone interested in insect farming or products and services related to that, such as free tutorials and training materials, farm management tool, AI mentor, webinars and recording archives, and soon also new BSF business calculators, a virtual neonate calculator and podcasts + a set of Premium features for the more advanced.

The obstacles

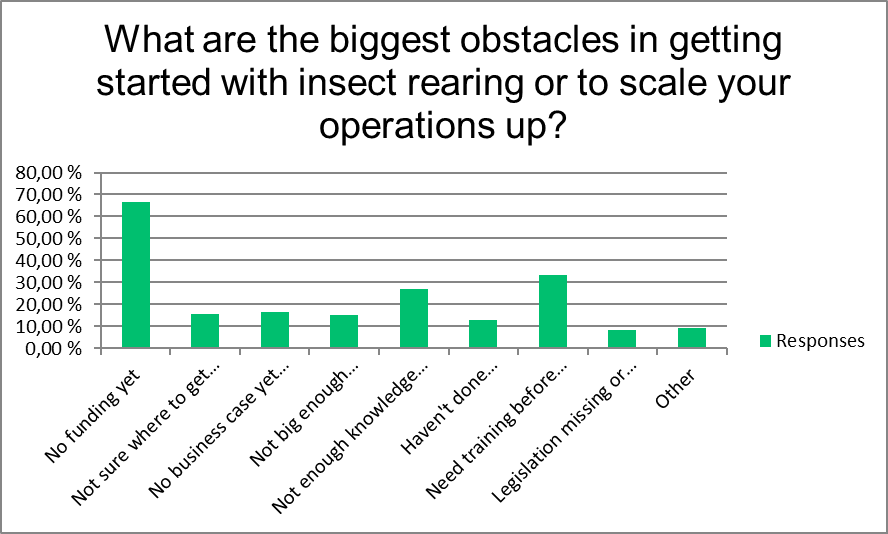

When asked in the Insect Industry Survey about the biggest obstacle to start farming insects or to scale up, our respondents stated the lack of proper funding being the number one issue. And even if there are great initiatives across the globe, especially in developing countries in Africa and in Asia to train people for insect farming, the 2nd most important obstacle was needing proper training before getting started, and the 3rd obstacle was not having enough knowledge to start the operations – both related to the same issue.

Gladly, the Insect Farm Hub got you covered on that also. As mentioned here above, the Farm Hub does offer free video tutorials, there are full courses, webinar recordings, and an AI mentor to answer any question you may have – and we’re training it get even better in answering relevant questions all the time.

The other notable obstacles didn’t fall far, as the next most important were “Not sure where to get suitable or affordable biowaste”, “No business case yet for the larvae and/or frass”, “Not big enough customers (yet)”, and “Haven’t done calculations yet to test the business case”.

A much smaller number of respondents of the Insect Industry Survey claimed that missing legislation or prohibiting the use of insects or upcycling biowaste were the obstacles that kept them from starting or scaling up their operations.

Biowaste upcycling

Those that were already farming or having calculations in place to do so in the near future, were asked how much biowaste they plan or already upcycle per month (kg). And the responses vary from 1-900.000 kg per month, what a range!

It may have happened that some of the respondents didn’t read the question carefully enough, and confused if the question was kg per day or month or of the amount was supposed to be in kg or in ton. Any which way, the range is still huge.

Those that upcycle or plan to upcycle 1-100 kg of biowaste per month represented c. 34% of all respondents, those that upcycle 150-5000 kg per month represented c. 37% of all respondents, and the rest of the respondents upcycle 6000-900.000 kgs per month. Notable, than of the biggest upcycle cases 2 stated the 900.000 kg sum, which may the same factory, 3 stated amount ranging from 100.000-120.000 kgs, while the rest of the big players or big plans were in the range of 6.000-12.000 kgs.

Why is the size so significant, you may ask. Well, those that upcycle 1-100 kg per month are likely to only upcycle their own and perhaps the neighborhood biowaste, meaning that they are very likely backyard insect farmers with perhaps nets, small composts, and manual work that they do to save in their own chicken feed costs or perhaps making a small side hustle with BSF where they get the biowaste for free and sell the larvae and/or frass.

When the production capacity is to upcycle 150-5000 kgs of biowaste per month, they are starting to get into the actual BSF business, and at the higher end of this scale, they may already run an operation with professional level BSF production unit(s), such as Manna MIND operated small facilities, green houses or insulated old sea containers. This requires small investment to get this kind of set up running, especially the bigger end of this scale is likely to have climatization in place to make the production more stable, predictable and generally professional with less manual work required.

As an example, one refurbished old sea container (20ft), small green house or storage room size operation with climatization is typically capable of upcycling 3-4.000 kg of biowaste per rearing cycle of 7-10 days, and the output is at the level of 500-600 kg of larvae and 700-900 kg of frass per cycle. If you run 7-day cycles, you can multiply these numbers by 3, but most would run 2 individual 7–10-day batches per month. This means that a 20ft container size operation with proper climatization technology can upcycle anywhere between 3-12.000 kg of biowaste per month – rough estimates.

Those that are upcycling or plan to upcycle more than 10.000 kg are likely to have at least a couple of smaller production units or an actual factory-level operation with perhaps some automation in place, meaning that the production setup alone costs at minimum hundreds of thousands of dollars, but the bigger end of this scale costs millions of dollars just to get the factory up and running. The amounts with factory-level operation have to be huge to make the setup profitable even in the long run with best case scenarios.

Production outputs

The next question in the Insect Industry Survey was related to the production size, but the output side; If you are already operating, how much larvae are you producing per month (kg)? Compared to the previous question size-related output estimates, if one is producing more than 500 kg of larvae per month, the set up is likely to be somewhat professional with relevant production unit, perhaps climatization, etc.

Out of all our respondents, at the moment operational units were only available or answer given by 50 respondents. Most of the respondents were still producing fairly small amounts, with only 20 producing more than 500 kgs per month, top production producing 48.000 kgs and only 6 producing more than 10.000 kg of larvae per month.

How much do BSF products cost?

The last question in the Insect Industry Survey was “How much do BSF products cost in your region?” Here are reference prices for you to consider when calculating your BSF business case:

- 1 gram of eggs is #1000 in Nigeria

- Frass cost up to 5 dollars per kg, while dried BSF costs 10 dollars per kg

- 750 Ksh per Kg

- Ksh 120 dry BSFL

- Live larvae ₦700 per kg

- Frass goes at around 6 million VND per ton

- Larvae at KES .50/KG

- 5000 idr/kg

- Larvae, 1 kg is #600 in Naira

- IDR 50.000-100.000/kg

- 1 kg of dried BSF larvae is 20 rupees and 1 kg of frass is 10 rupees

- 750 RS Per kg

- Lagos: Dry Lavae is about 850 Naira/kg

- South Africa: 1 crate R 150

- Maggots meal K1500, Lusaka Zambia

- BSF dried – 2,500/ TZS (1 kg). BSFFF – 150,000/ TZS (1 MT)

- BSF larvae, 200,000 Malawi Kwacha per Kg

- 7 USD per kg

- Larva 1 Kg about 2000 Ugandan Shillings

- Whole Dried Black Soldier Fly Larvae – 60 grams packed for ₹ (inr) 150

- Live larvae, $20 / 100g

- Fresh Larvae: 700 Nigerian Naira per kg. Pre-Pupae: 7,000 Nigerian Naira.

- Zambia: R230 per kg, live larvae R200 per kg and BSF frass R30 per litre

- 320 birr/kg

- BSFL eggs N600, live BSFL N700-800, dried or puffed BSFL N1500 Naira

- Dried larvae R80/kg, frass R68/kg

- Eggs (gr): $60.000 COP

- Dried Larvae cost P5.00/kg

- AUD$2,500 defatted meal, AUD$300+ / ton frass

That’s all this time around. Please do join our next Insect Industry Survey again later in 2025 where we ask somewhat different questions. In the meantime, please check out our other blog posts, follow us at Linkedin, Facebook, Instagram and YouTube, and join the free Insect Farm Hub and the Marketplace at https://insectfarmhub.com

Learn more about BSF farming in the

Insect Farm Hub!

Manna Insect has launched a comprehensive insect farming platform designed for learning, managing, monitoring and networking. There are tons of free content about insect farming, as well as a lot of paid premium content, that dives even deeper in black soldier fly business.